Keeping the Classic Cars Rolling

At Dualtone, we have been delivering the best car care since 1946. While we pride ourselves on our state-of-the-art

expertise, we have not lost our love of the oldies. Unfortunately, older cars may suffer more than newer from deterioration

from worn rubber, rust and a general wearing of parts. You may consider replacing an old single cylinder system with an

update without losing the vehicle’s original charm. Plus, the safety factor would be greatly increased, as the old braking

system may be susceptible to issues such as losing power.

Call Us from the La Jolla and Pacific Beach Areas

At Dualtone, we want to make sure your vehicle is functioning at peak performance. For diagnostics, wheel alignment

or maintenance in San Diego, La Jolla and Pacific Beach, give us a call at (858) 273-8745.

Expert Brake Repair in San Diego

Dualtone Automotive 4745 Mission Bay Dr. San Diego, CA 92109 © Dualtone Automotive Inc. 2015

Serving San Diego Since 1946

Phone: (858) 273-874 (619) 276-4525

8:00am-500pm

8:00am-200pm

Closed

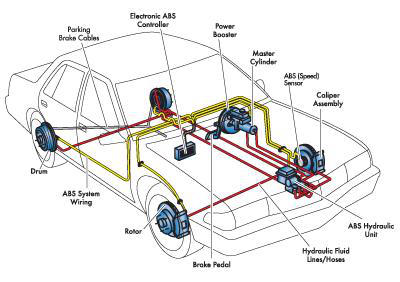

At the heart of the system is the master cylinder. Symptoms of a failing master cylinder include a low, spongy or fading

brake pedal.

The brake booster multiplies the force applied by the driver to the brake pedal. The most common boosters operate

using vacuum, while others use hydraulic pressure generated by the power steering pump. A failing booster usually creates

a hard to push brake pedal and may be accompanied by a hissing noise coming from the area around the brake pedal.

Brake fluid naturally attracts moisture, which can penetrate even sealed systems. When it does, it causes the brake

fluid boiling point to lower, increasing the chances of corrosion and poor braking. We can test, and if necessary replace your

brake fluid to help reduce this risk, and to prolong the life of brake components.

The only thing worse than a car that won’t start, is one that won’t stop. Despite being the vehicle’s primary safety system,

the brakes are often overlooked until they begin to exhibit symptoms. If you are experiencing any of the following symptoms

you should have the skilled technicians at Dualtone inspect your brakes as soon as possible. Not only can be dangerous to

ignore such warning signs but, small brake problems that are left unrepaired can lead to expensive damage to other parts of

your braking system.

•

Your brake light is on

•

Squealing or grinding noises

•

Pedal is almost to the floor before it engages

•

Pedal is difficult to push

•

Brakes grab too easily or the light on the dashboard stays on

•

Pedal vibrates even under normal braking conditions

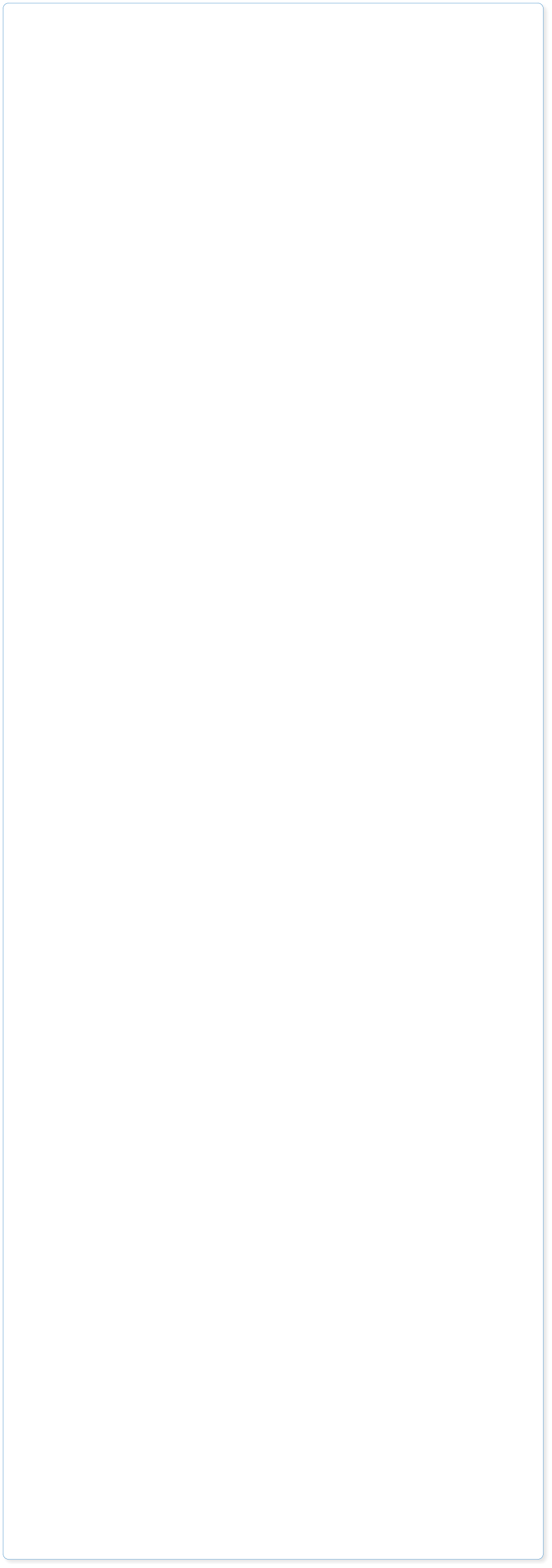

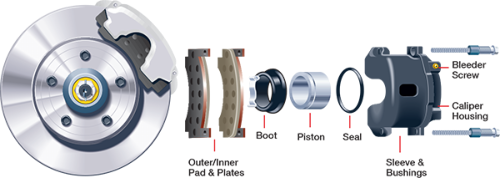

Disc Brake System

The disc brake system is used on the front brakes of all modern cars and trucks has also become the preferred system

for the rear brakes on many vehicles. The system uses a caliper to apply hydraulic pressure from the master cylinder to the

brake pads which apply a clamping force on the brake rotor. The main components of this system include:

•

caliper assembly

•

brake rotor or disc

•

brake pads

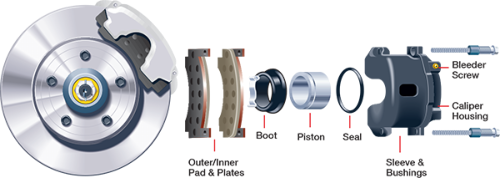

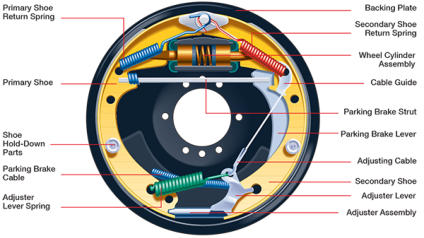

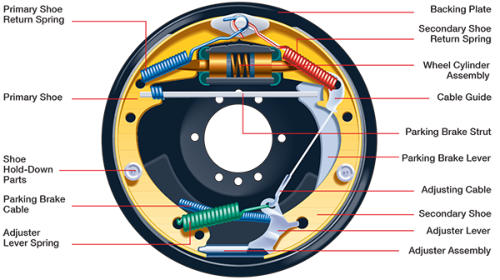

Drum Brake System

When replacing the brake pads we always recommend resurfacing the rotors. Resurfacing provides a proper finish for

new brake pads to mate with, helping prevent brake vibration and pulsation. Many times we also recommend replacing the

disc brake hardware, these are the metal clips and the rubber bushings in the caliper that allow the brake pads to contact the

disc evenly and then return to their resting position. When these items wear they can keep the brake pads held against the

rotor and cause premature wear of system components

Drum brakes work much like disc brakes, by applying friction to a spinning surface to slow and then stop the vehicle’s

momentum. In drum brakes, brake shoes press against the inside of a drum instead of a rotor to create this braking action.

The main components of this system include:

•

wheel cylinder

•

brake shoes

•

brake drum

•

drum brake hardware (springs, fasteners)

When replacing the brake shoes we always recommend resurfacing the drums. Resurfacing provides a proper finish for

new brake shoes to mate with,as well as ensuring the contact surface is perfectly circular, helping prevent brake vibration. Just

as with disc brakes the drum brake system has supporting brake hardware, these are the springs that help return the shoes to

their resting position and attaching fasteners that hold them in place. Over the life of the shoes and several thousand

applications of the brakes these components can weaken and can lead to noise and uneven brake wear

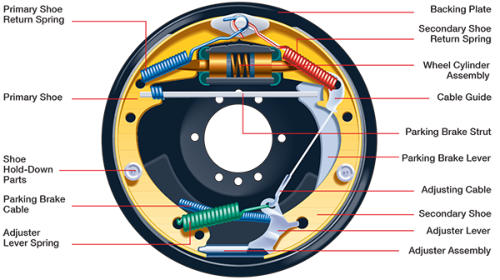

Hydraulic System

In a hydraulic brake system, when the brake pedal is pressed, a pushrod exerts force on the piston(s) in the master

cylinder, causing fluid from the brake fluid reservoir to flow into a pressure chamber through a compensating port. This

results in an increase in the pressure of the entire hydraulic system, forcing fluid through the hydraulic lines to the calipers

and/or wheel cylinders. Subsequent release of the brake pedal allows the spring(s) in the master cylinder assembly to return

the it’s piston(s) back into position. This action relieves the hydraulic pressure on the calipers and wheel cylinders allowing

the brake pads and shoes to return to their resting positions away from the rotor or drum. The hydraulic system in most

vehicles consists of:

•

master cylinder

•

power brake booster

•

pressure control valves (ABS, proportioning)

•

metal brake lines

•

rubber brake hoses

•

calipers / wheel cylinders

•

brake fluid